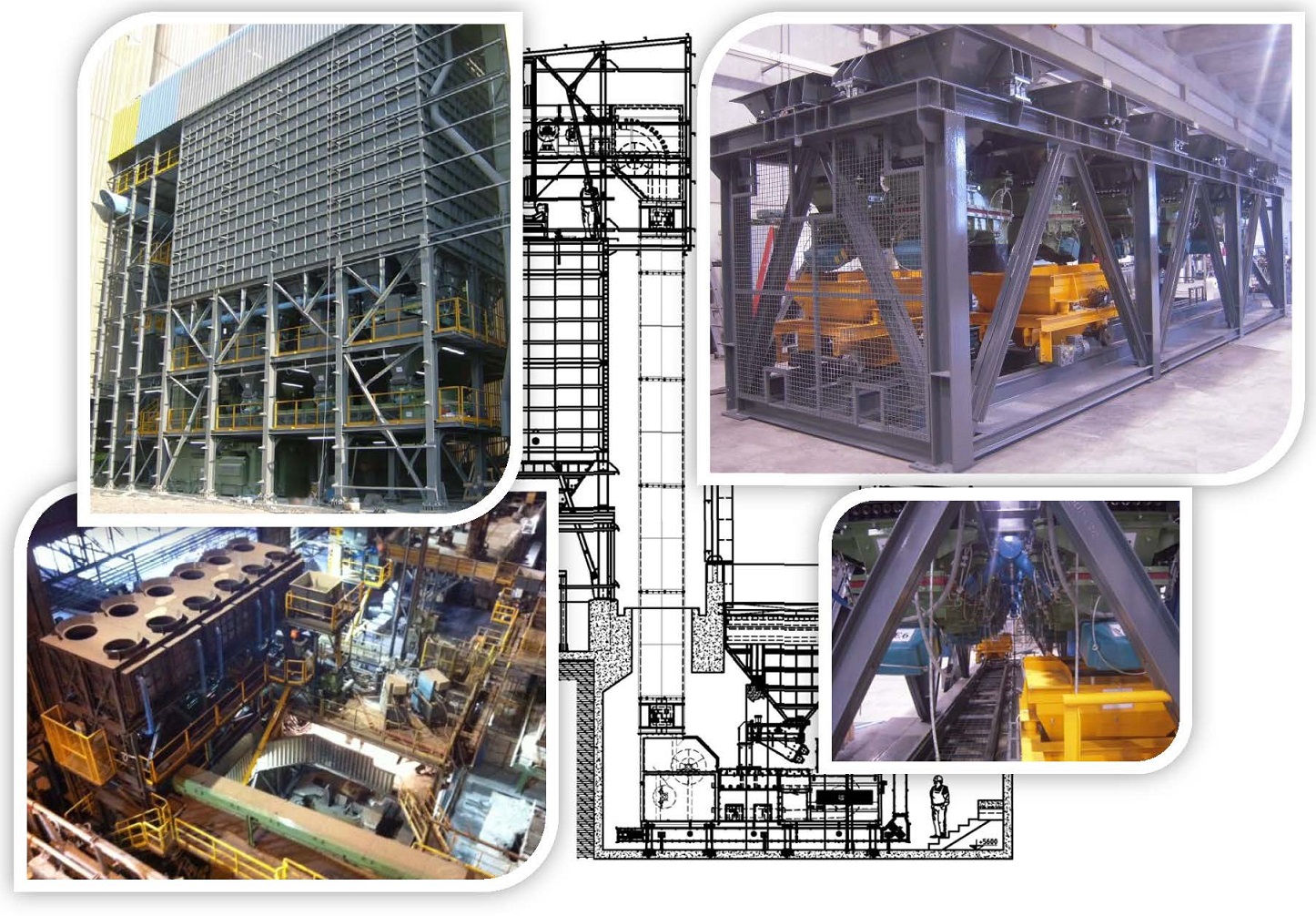

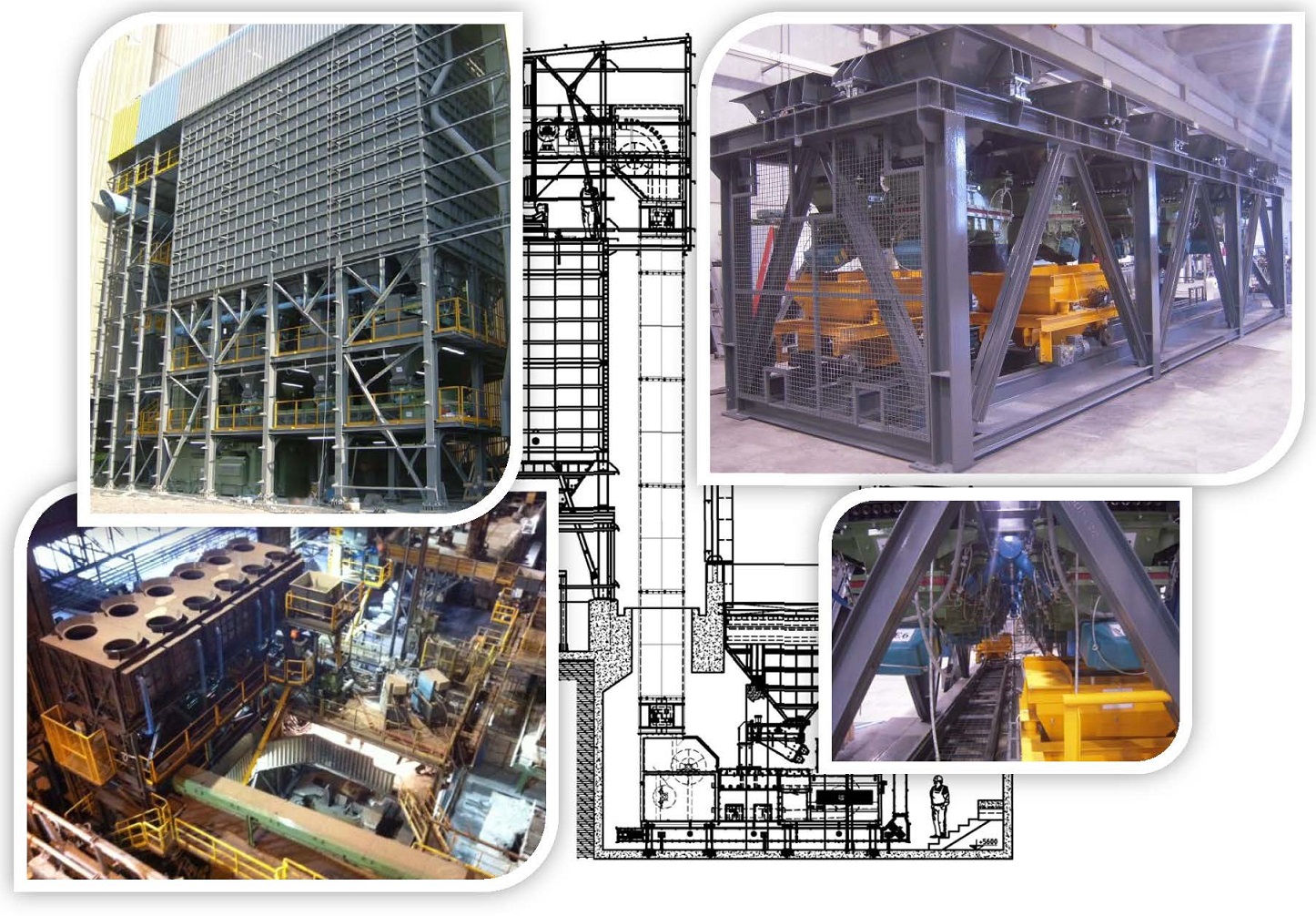

Impianto additivi e ferro – leghe

Stoccaggio, dosaggio e trasporto in forno o siviera di ferro – leghe e calce, i materiali sono stoccati in tramogge (o sili) modulari con una capacità tipica compresa tra 5 e 200 m³.I materiali sfusi sono estratti dai sili o tramogge mediante canali vibranti e/o coclee. In funzione delle esigenze produttive, i materiali vengono dosati mediante una o più tramogge pesatrici, da cui vengono convogliati al forno o siviera mediante nastri trasportatori, o nastri navetta, o recuperatori, o tramogge carrellate in funzione delle condizioni logistiche o di processo.

La dimensione del materiale sfuso gestito è compresa tra 5 e 200 mm. ed è stoccato in batterie di sili aventi mediamente 1.000 m³ di capacità, con una tramoggia di (ricevimento) scarico da autocarro da 35 m³.

Il progetto di base dell’impianto consente la realizzazione di sistemi estremamente versatili e personalizzabili in svariate varianti.