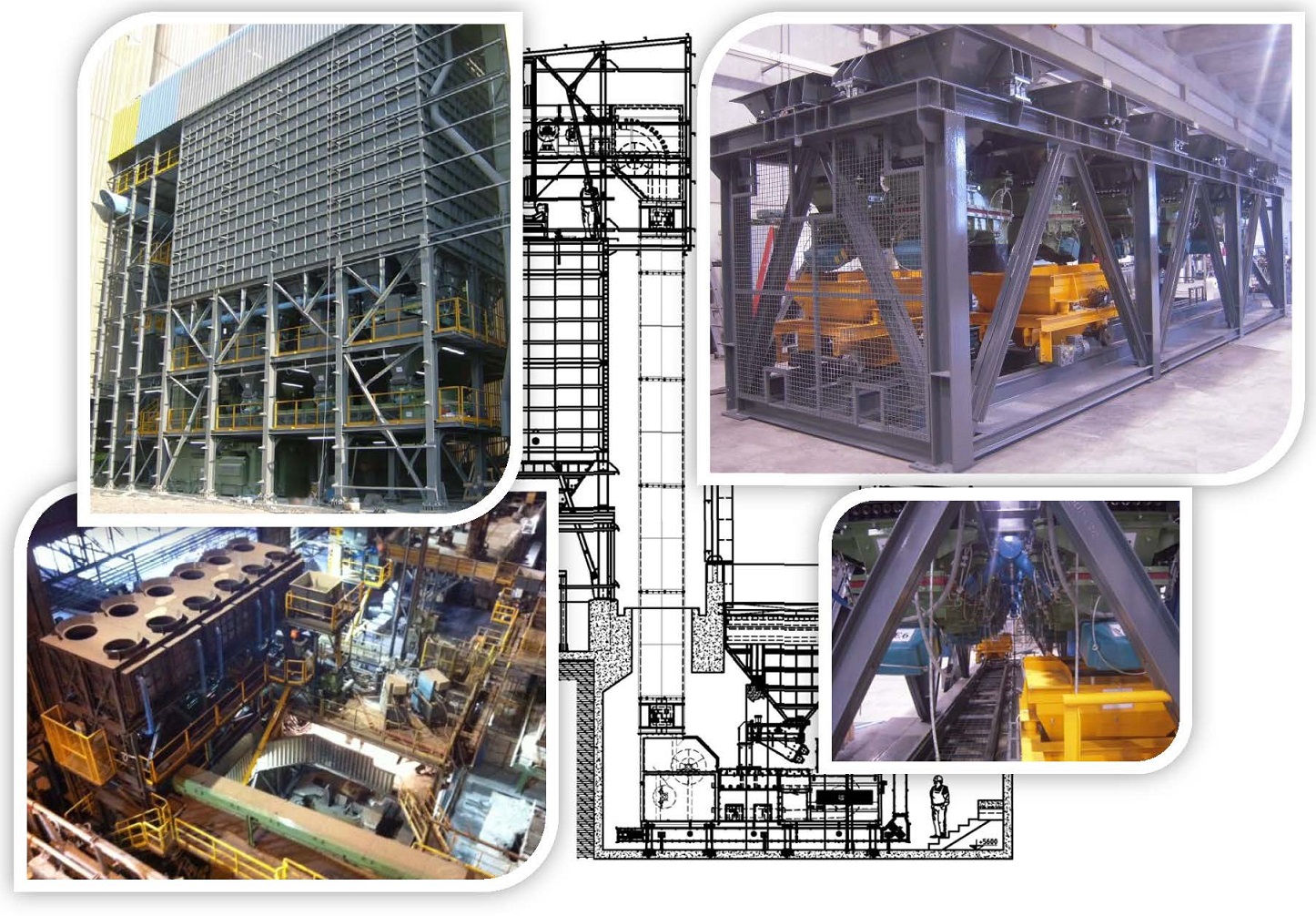

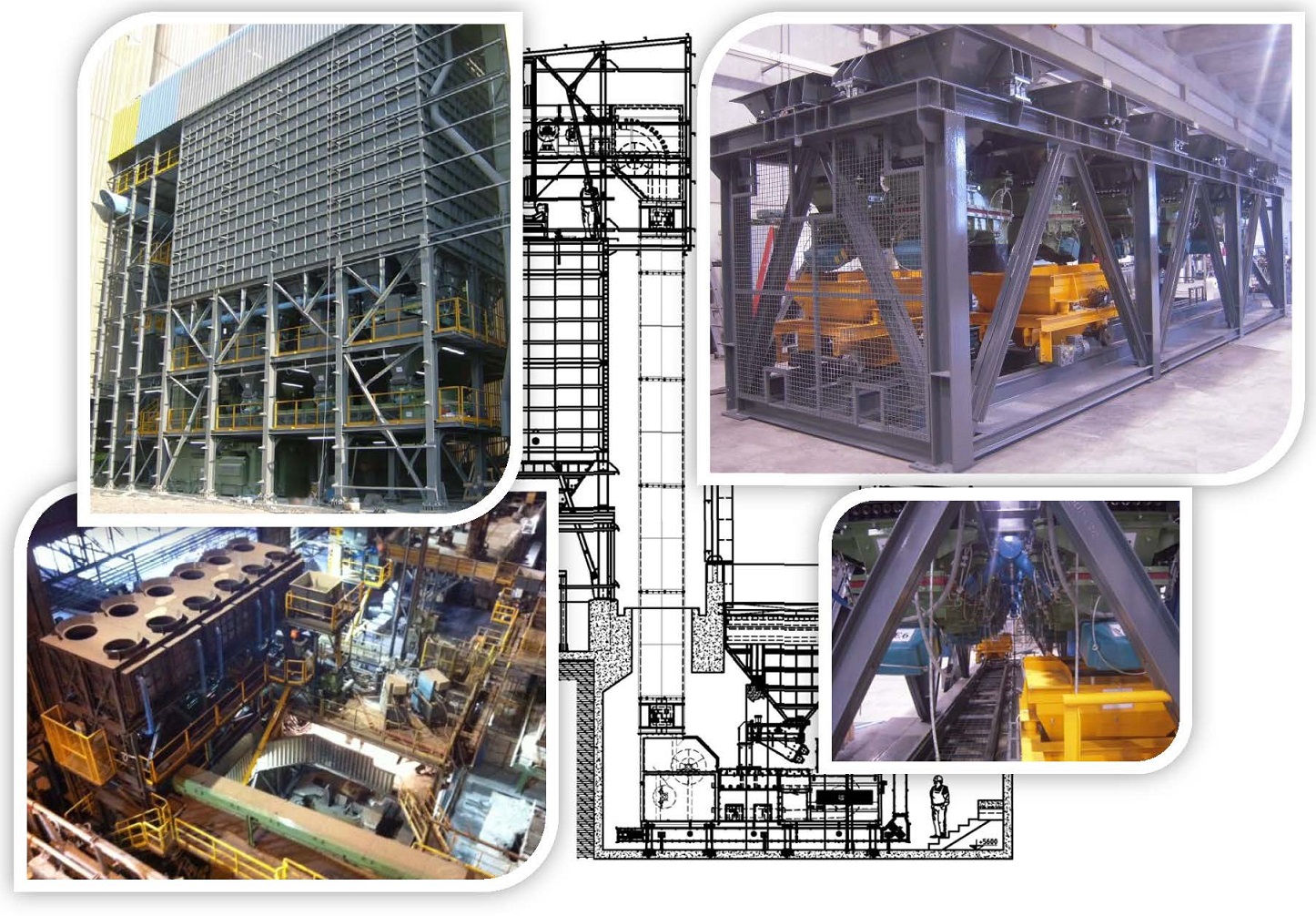

Alloys and additives systems

Alloys and additives to be dosed, batched and carried to a furnace or to a ladle are stored in modular hoppers with a typical capacity between 5 and 200 m³.

Bulk materials are extracted from stirage bins or hoppers by vibrating or feeders or tubolar screws in according to the process requirements.

The needed amount of each material is extracted from related storage hopper and batched (in a weighing hopper fix or travelling under the hoppers’ battery or on a weighing belt conveyor) then conveyed to the furnace or to the ladle.

Handled bulk material size is between 5 and 200 mm.

Alloys and additives bins battery 1.000 m³ capacity with a single weighing truck discharging hopper with 35 m3 capacity

The basic design of the plant allows the creation of extremely versatile and customizable systems in various variants.